【IMPORTANT】An Overview of Inspection & Detection Exhibitors in Interpipe 2020

Pipeline has been widely used in the world as a safe and economical means of transporting large quantities of oil, gas and other energy. At the same time, topics such as pipeline maintenance management, prevent leakage and how to ensure the safe operation of pipeline has become important. However, to improve the safety management of oil and gas pipelines in China, improvement of detection and inspection technology of long-distance pipelines is in great necessary. Up to now, the Interpipe 2020 has attracted many companies worldwide in testing and detection field to display their equipment, technologies, services and systems. Please see the following that Interpipe 2020 will show you some advantage of those enterprises.

APC Integrity Technologies have been providing inspection and monitoring services to the Oil & Gas industry since 2002. The company is in the integrity business with the focus on supporting pipeline and facility operator with technologies to drive value improvement and exceed the HSSE expectation for safe operations. At present, APC has formed a strategic alliance with first class companies

APC is a full-service firm offering a selection of Field & Testing Service, such as Remote Monitoring Service, Guided Wave Inspection, Intelligent Pigging, Advanced DNE Testing on pipe and tank, ad pipeline cleaning services. Additionally, APC International Group offers Gas Turbine service and Asset Integrity Management to the Oil & Gas Industry.

APC Integrity Technologies is headquartered in Beijing and has its regional headquarter in British and Canada, and its strategic partners are distributed in Germany, Italy, the Netherlands, Switzerland and the United States. Also, it established Internal Inspection R&D and Commissioning Center at Beijing with ROSEN. APC is oriented to provide international first-class technical services or high-end products, highlighting the distinctive personality of professional technical services, making international technology localization and customization.

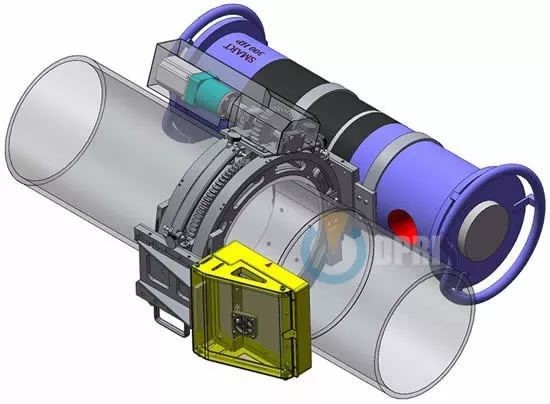

SICHUAN DPRI Technology Co., Ltd. (Booth No. TB31)

SICHUAN DPRI Technology Co., Ltd was founded in November 2012 at Mianyang city, Sichuan Province. It is specialized in the R&D, production, sales and service of pipeline weld detection system and other radiation imaging system. It is a civil-military integration and high-tech enterprise jointly funded by China Academy of Engineering Physics and ENN Group, which is suitable for the development of modern enterprises.

Relying on the professional R&D platform of the Institute of Applied Electronics, China Academy of Engineering Physics, and the National X-Ray Digital Imaging Instrument Center, the company developed the first set of digital pipeline weld detection system in China -- WS System, and first time applied the digital real-time imaging system to the online detection of oil pipeline weld.

The company has participated in the formulation of two related industry standards, and has 15 patents of various types. It has obtained honors of the high-tech enterprise, military-civilian integration enterprise, military security grade iii qualification, CMA certification, etc. WS system has been recognized as the first set in China.

Langfang New Thinking Technology Co. Ltd. (Booth No. TB21)

Langfang New Thinking Technology Co. Ltd. was founded in 2008, is a leading NDT technology solution and products provider. After years of efforts, the company has become a national high-tech enterprise and won many honors including 8 patents of independent intellectual property rights.

The company is mainly engaged in ultrasonic phased array imaging, special pipeline crawler, DR, CR and system integration. Products involved in the fields of aerospace, military, petroleum and petrochemical, pressure vessels, long-distance pipelines, metallurgical manufacturing, ships, etc. Our company's independent R&D and scanning products which are special customized according to customer testing needs obtained the consistent high praise.

With cost-effective products and high-quality service, the company established positive relations of cooperation with many large enterprises, such as the Petroleum Pipeline Bureau, Sinopec Inspection Centre, Offshore Oil Engineering, Shanghai Bao Steel Group Corporation and so on.

Hangzhou Jianwei Mechanical & Electrical Technology (Booth No. B66)

Jianwei Technology is a one-stop closed loop solution provider engaged in modern mechanical simulation analysis, testing (monitoring), process stress elimination and ultrasonic nondestructive testing.

The leading products of the company include: ultrasonic stress meter (USG series), ultrasonic stress measurement module (USGNet), ultrasonic flaw detection board card (UTNet), wind power flaw detection equipment (WBM series), Internet of things + ultrasonic testing and non-standard ultrasonic testing system customization. Among them, the ultrasonic stress meter, ultrasonic stress measurement module and wind power flaw detection equipment are first used in China. USENet and UTNet which based on kilomega network introduced NDT into the Internet of things era.

In addition to that, ultrasonic instrument and the module lead by the company has designed the interface with secondary development kit simultaneously the high expansion ability, that not only have the ability on fixed point detection in complex environment, but also can face the large-scale nondestructive inspection system integration.

Shandong Ruizhi Electric Testing Instrument (Booth No. B56)

Shandong Ruizhi Electric Testing Instrument was founded 2003, it is a high-tech enterprise that obtained national certification and is a leading testing equipment manufacturer. The company integrates R&D, production, sales and service into one, and professionally provides testing instruments and comprehensive technical solutions.

At present, the company has 3 holding companies and several offices, and its products are involved in ultrasonic testing, coating testing, buried pipeline testing, infrared testing, gas testing and other fields. Its products include Ultrasonic thickness gauge (HCH series), coating thickness gauge (MC series), MCW eddy current thickness gauge, buried pipeline detector (FJ series ), EDM leak detector (DJ series),LED view lamp (GP series), black and white densitometer (HM series ), infrared temperature gauge(TM series), Richter hardness tester(YD series), etc.

Beijing Stress Analysis Technology (Booth No. B65)

Beijing stress analysis technology co., ltd. is a technical service company that mainly sells engineering stress-related technical consulting services (stress simulation, fluid simulation), stress testing (ultrasonic stress testing, buried pipeline stress concentration scanning (SCT) and stress analysis software (ANSYS), and also engages in technical training and software development.

The technical backbones are senior engineers with rich experience in engineering design, familiar with engineering specifications, proficient in finite element analysis, and can provide services in Chinese, English and Russian.

The company specializes in providing engineering and technical services in stress calculation, testing and simulation for petrochemical industry, pressure pipeline&vessel, mechanical engineering, environmental engineering and other industries, and have in-depth research in the fields of pipeline and equipment vibration, buried pipeline, submarine pipeline, frozen soil, welding simulation, phase inversion analysis, etc.

Company will always try their best to solve engineering problems for customers to enhance their core competence! Company look forward to cooperating and communicating with friends from all sides.

Shandong Jining Luchao Ultrasonic Equipment (Booth No. B15)

Shandong Jining Luchao Ultrasonic Equipment was located in one of the most historical cities–Jining, is a high-tech enterprise of development and production of power ultrasonic cleaning equipment and non-destructive testing instruments. It has advanced experience of more than ten years production of ultrasonic equipment, high-quality staffs, advanced management concept, strong technical force, excellent processing and testing equipment, hundred varieties of nondestructive testing instrument of ultrasonic equipment to produce 3 kinds of equipment including power ultrasonic cleaning equipment and ultrasonic extraction equipment.

Since its establishment, Luchao has been constantly committed to the research and manufacture of new equipment and the development of new technology, and has maintained cooperative relations with many universities and colleges. The unique ultrasonic transducer and high-power module power supply technology of Luchao enjoys a high reputation in China.

Beijing Guodian NDT (Booth No. B58)

Beijing Guodian NDT Co., Ltd.is a specialized non-destructive testing company – engaging itself in research and development, production of NDT equipment and offering metal materials analysis and NDT technology services.

Highly efficient and innovative technicians lay strong technical force for our company. We employ more than 200 professional technicians and engineers and many NDT specialists in power industry. More than 20 percent of the employees have doctorate or master's degree and the title of senior engineer. We built 2,000 square meters of development and test base and established advanced electronic mounting room, machining workshop and metal lab. The machining workshop is provided with advanced devices, such as machining center, CNC lathes, wire cutting machine and electro-discharge machines. The electronic mounting room is equipped with chip mounter, reflow soldering, wave soldering, screen printer, laser marking machine, production line, etc.

The NDT products we developed include industrial endoscope, rechargeable variable-frequency magnetic detector, stainless steel oxide scale and flaw detector, alloy element analyzer, eddy current endoscope, flashlight DVR, smart flashlight, industrial testing crawing robot, etc. More than 20 products are patented and 14 software copyrights are authorized. Magnetic viewing film is known as a revolution of magnetic particle inspection in the field of non-destructive testing.

The company has been authorized with Inspection and Testing Institution Approval Certificate of Special Equipment of People’s Republic of China, Rating Certificate for Special Equipment Non-Destructive-Testing Inspection Agency, Grade B Qualification of Engineering Consulting Entity, National Certificate of High & New Technological Enterprise, Certificate of High & New Technological Enterprise of Zhongguancun Science Park, QES Three Management Systems Certification, and Radiation Safety Permit. Can independently carry out third-party inspection services, can undertake various industries of boilers, pressure vessels, pressure pipes, large storage tanks, steel structures and other special equipment nondestructive testing and metal material physical and chemical inspection technical services.

Tianjin Genius Technology & Equipment (Booth No. A09、A10)

Tianjin Genius Technology & Equipment is a high-tech enterprise that engaged in buried pipeline testing technology and professional software development, corrosion testing equipment development and sales. The operation concept is by introducing and absorbing advanced technology, equipment and management experience globally, adhering to the market-oriented, high-tech research and development as the basis, through continuous independent innovation and technological progress, to build the core competitiveness, committed to China's corrosion detection industry technology and equipment to provide quality services.

Since company founded in 1994, after more than 20 years of unremitting efforts, the company has now developed their business in more than 30 provinces in China, and become a technology leading professional company in corrosion detection and evaluation field. It obtained the National high and new technology enterprises in 2016, and recognized as State-level science and technology enterprise in 2017.

The company's business services include: developing and selling the series of inspection system and evaluation software for buried pipeline corrosion and protection, constructing pipeline integrity management system for industry users, and undertaking engineering project services; Sales of ROV system for underwater pipeline testing, JX-MTM magnetic memory testing and evaluation system, DCVG/CIPS series testing equipment, SCM stray current testing system, buried pipeline anti-corrosion layer detector, detector series products; Provide technical consulting and engineering services for pipeline inspection, fault diagnosis of cathodic protection system, stray current detection and treatment, direct evaluation of corrosion (ECDA), etc.; undertake the underground pipeline corrosion status evaluation and inspection project and provide the corresponding technical services.

Based on its rich experience in pipeline detection, evaluation of corrosion detection, stray current, cathodic protection and other fields of technology development and engineering , it has carried out outside corrosion testing and evaluation (ECDA) project, stray current detection and governance, Yin bao system fault diagnosis and maintenance and other technical services, provides a full range of technical and engineering services. for PetroChina, Sinopec, Sichuan gas to east, Beijing gas group, represented by the west-east gas users.

Qingdao Marine Equipment Inspection & Testing (Booth No. B13)

Qingdao Marine Equipment Inspection & Testing is a municipal wholly state-owned company approved for establishment in 2016. Its main function is to develop the inspection and testing industry, featuring the inspection and testing of Marine equipment and high-end equipment, and promote the coordinated development of the inspection and testing industry chain. Main business structure is the inspection and testing industry, quality technology solutions and related supporting industries, technology and financial services. It has built and operated three state-level innovation platforms, namely the national Marine equipment quality inspection center, the national engineering laboratory of Marine underwater equipment testing and testing technology, and the national platform for R&D, testing and testing of major Marine equipment products. It has 5 core first-level subsidiaries and nearly 10 participating subsidiaries.

The company has passed the qualification assessment of CNAS, CMA and DILAG, and passed the certification of CCS by China classification society. It can provide Marine engineering equipment, oil and gas equipment, new energy equipment, inspection, testing and certification services for mechanical properties of materials and related fields such as lean fatigue. Its main clients include Marine engineering equipment manufacturing worldwide and related supporting production enterprises, Marine oil and gas field development, classification, scientific research institutions, administrative department of Marine, etc. It provides technical support for the research and manufacturing of China's Marine engineering equipment, promotes the integrated development of high-end firewood manufacturing and inspection and testing industries, and helps Qingdao to build an international Marine city and serve the strategy of becoming a maritime power.

Beijing Keli Hua 'an Geological Disaster Monitoring Technology

(Booth No. B53)

Beijing Keli Hua 'an Geological Disaster Monitoring Technology is the only equipment supplier and technical service provider specializing in geological disaster risk monitoring of long-distance oil and gas pipelines in China. It is long-term commitment to the effective integration of the application of high and new technology, to achieve the best monitoring effect with the lowest possible input.

The company now completed a series of projects include geological hazards monitoring network, landslide, goaf settlement of emergency monitoring, emergency monitoring displacement monitoring pipe and gas pipe with pressure lift tube dynamic monitoring for nearly ten pipeline construction and operations under PetroChina, Sinopec, and obtain recognition from owner side for their rigorous, realistic, quick response working style.

As the first institution engaged in pipeline geological disaster monitoring in China, the stress-strain monitoring and analysis system independently developed by the company fills the gap of pipeline mechanics monitoring in China, and has the largest and most comprehensive strain monitoring database of long-distance oil and gas pipeline in China. Based on the experts strength from mechanics of Chinese academy of sciences, state seismological bureau, China geological environmental monitoring institute, China university of petroleum, China university of geosciences, China university of mining and other institutions , the company aims to build a whole society oriented, open and cooperative research platform, to provide practical solution to the safe operation of domestic long distance oil and gas pipelines.

CYG Changtong New Material (Booth No. B08、B09)

CYG Changtong New Material Co., Ltd is a national high-tech enterprise integrating R&D, production and sales of pipeline corrosion protection materials, heat shrink Insulation material, telecommunication accessories and PET heat shrinkable sleeve into one. It has passed and obtained ISO 9000 Quality Management System certification, ISO 14000 Environment Management System certification, OHSAS 18001 Occupation Health Safety Management System certification.

Scope of business: R&D, Sales, technical service and site installation service as well as varied coatings sales and service (excluding the flammable, combustible and toxic dangerous chemicals) such as the pipeline corrosion protection heat shrinkable materials, heat shrinkable (torch heated) pressure sensitive tapes, heat shrinkable tube, heat shrinkable sleeve, PET shrinkable sleeve, hot melting adhesive, cold-applied tapes, viso-elastic anticorrosion materials, flexible anode riveting, optical cable termination box, magnesium anode, zinc anode, aluminum anode, buried long-acting reference electrode, test pile, epoxy FRP, photo-curing protection sleeve, underground PE warning sheet or tape, PET heat shrinkable sleeve (film).

In addition to the above-mentioned companies, PetroChina Inspection Technology, Sinopec long-distance oil and gas pipeline inspection, CNOOC Technology Testing will also engage in the Interpipe 2020. Inspection and detection as one of the most important part of Interpipe 2020, a specific exhibition area is planned to better service companies of inspection, testing and detection of oil and gas pipelines.

Welcome to the Interpipe 2020 on September 15-17, 2020.